Understanding the Importance of Tension Bars in Structural Engineering

The world of structural engineering is a complex and intricate field that plays a crucial role in our daily lives. From skyscrapers that define city skylines to bridges that connect communities, the structural integrity of these constructions relies heavily on various components. Among these components, tension bars serve a vital function that is often overlooked.

Tension bars are structural elements designed to withstand tensile forces, helping to maintain the stability and safety of structures. As buildings and infrastructures are subjected to various loads and environmental conditions, the role of tension bars becomes increasingly significant. Whether it’s a high-rise building or a simple pedestrian bridge, the presence of tension bars can mean the difference between a secure structure and a potential failure.

Understanding the importance of tension bars in structural engineering not only highlights their role in maintaining safety but also underscores the need for proper design, material selection, and installation. In this article, we will explore the various aspects of tension bars, their applications, and their impact on structural integrity, thereby providing a comprehensive view of their significance in the engineering world.

The Role of Tension Bars in Structural Systems

Tension bars serve a fundamental purpose in structural systems, acting as crucial components that help to manage the forces exerted on a structure. Their primary function is to resist tension, which is a pulling force acting on an object. These bars are typically made from high-strength materials, such as steel or reinforced composites, which enable them to endure significant loads without deformation.

One of the most common applications of tension bars is in truss systems. Trusses are frameworks consisting of triangular units, and tension bars are integral to maintaining the shape and stability of these structures. In a truss, tension bars counteract the compressive forces acting on other members, providing a balanced load distribution across the entire framework. This balance is essential for preventing structural failure, particularly in environments prone to dynamic forces, such as wind or seismic activity.

In addition to trusses, tension bars play a critical role in various architectural elements, including roofs and bridges. For instance, in cable-stayed bridges, tension bars connect the main cable to the bridge deck, ensuring that the deck remains stable and secure as loads are applied. This application demonstrates how tension bars are not just passive elements; they actively contribute to the performance and longevity of the structure.

Furthermore, the design and placement of tension bars require careful consideration by structural engineers. Factors such as the expected load, material properties, and environmental conditions must be taken into account to ensure optimal performance. This level of attention to detail highlights the importance of tension bars in the overall design process, as improper installation or inadequate sizing can lead to catastrophic failures.

In summary, tension bars are indispensable in various structural systems. Their ability to withstand tensile forces while contributing to the overall stability of structures makes them a vital element in the field of structural engineering. Understanding their role enables engineers to create safer and more resilient designs, ultimately enhancing the safety and functionality of our built environment.

Material Selection for Tension Bars

The material chosen for tension bars significantly impacts their performance and durability in structural applications. Engineers must consider various factors, including strength, corrosion resistance, and weight, when selecting materials for tension bars to ensure they meet the specific needs of the project.

Steel is one of the most commonly used materials for tension bars due to its high tensile strength and durability. Structural steel, often treated to enhance its properties, can withstand substantial loads, making it an ideal choice for various applications. Additionally, steel can be easily fabricated into different shapes and sizes, allowing for flexibility in design.

However, while steel offers many advantages, it is also susceptible to corrosion, particularly in environments exposed to moisture or chemicals. To combat this issue, engineers often employ protective coatings, such as galvanization or powder coating, to enhance the longevity of steel tension bars. Moreover, stainless steel is an alternative that provides excellent corrosion resistance, making it suitable for marine or industrial applications where exposure to harsh conditions is a concern.

In recent years, the use of composite materials for tension bars has gained popularity. Fiber-reinforced polymers (FRPs) are lightweight yet strong alternatives to traditional materials. These composites offer excellent resistance to corrosion and can be molded into complex shapes, providing additional design flexibility. However, their higher cost and limited track record compared to steel can be barriers to widespread adoption.

The selection process for tension bar materials also involves evaluating the environmental impact and sustainability of the materials used. With growing concerns about climate change and resource depletion, engineers are increasingly tasked with choosing materials that reduce the carbon footprint of their projects. This may involve selecting recycled materials or exploring innovative manufacturing processes that minimize waste.

Ultimately, the choice of material for tension bars is a critical decision that influences the performance, safety, and sustainability of structural designs. Engineers must balance performance requirements with cost considerations and environmental impacts to ensure that the selected materials meet the project’s needs while adhering to best practices in structural engineering.

Design Considerations for Tension Bars

Designing tension bars involves a comprehensive understanding of both the structural requirements and the forces they will encounter throughout their lifecycle. Several key design considerations must be addressed to ensure that tension bars perform effectively and enhance the overall stability of a structure.

Firstly, the load conditions must be clearly defined. Engineers need to analyze the types of loads that the tension bars will experience, which can include static loads from the structure itself and dynamic loads from environmental factors such as wind, seismic activity, or even human traffic. This analysis helps in determining the adequate size, shape, and material of the tension bars.

Another essential aspect of design is the connection points where tension bars are anchored to other structural elements. Proper detailing at these connection points is critical for ensuring that the tension forces are effectively transferred without introducing stress concentrations that could lead to failure. Engineers often employ various connection techniques, such as bolting or welding, and must account for the potential for fatigue over time, especially in structures subject to cyclic loading.

The length and cross-sectional area of the tension bars also play a significant role in their effectiveness. A well-designed tension bar should be long enough to distribute stresses evenly while also being sufficiently robust to carry the anticipated loads. Engineers often perform mathematical calculations and simulations to optimize these dimensions, ensuring that the tension bars can perform without excessive deformation or failure.

Moreover, safety factors are integral to the design process. Engineers typically incorporate safety factors into their calculations to account for uncertainties in load predictions, material properties, and construction methods. This practice helps ensure that tension bars will perform safely under anticipated conditions, providing an additional layer of protection against potential structural failures.

Lastly, ongoing maintenance and inspection considerations should also be part of the design process. Even the best-designed tension bars may require periodic evaluation to ensure they remain in good condition over time. Engineers must develop strategies for inspection and maintenance, which can include visual checks, non-destructive testing, and replacement protocols if deterioration is detected.

In conclusion, the design of tension bars is a multifaceted process that requires a deep understanding of structural behavior, material properties, and construction techniques. By addressing these design considerations, engineers can create safe and effective tension bars that contribute significantly to the overall performance and longevity of structures.

The Future of Tension Bars in Engineering

As the field of structural engineering continues to evolve, so too do the innovations surrounding tension bars. The future of tension bar technology is likely to be shaped by advancements in materials science, design methodologies, and construction practices.

One of the most exciting developments is the ongoing research into advanced materials such as high-strength composites and smart materials. These materials possess unique properties that can enhance the performance of tension bars. For instance, smart materials can change their properties in response to external stimuli, potentially allowing tension bars to adapt to varying loads and environmental conditions in real-time. This adaptability could significantly improve the resilience of structures to extreme weather events or seismic activity.

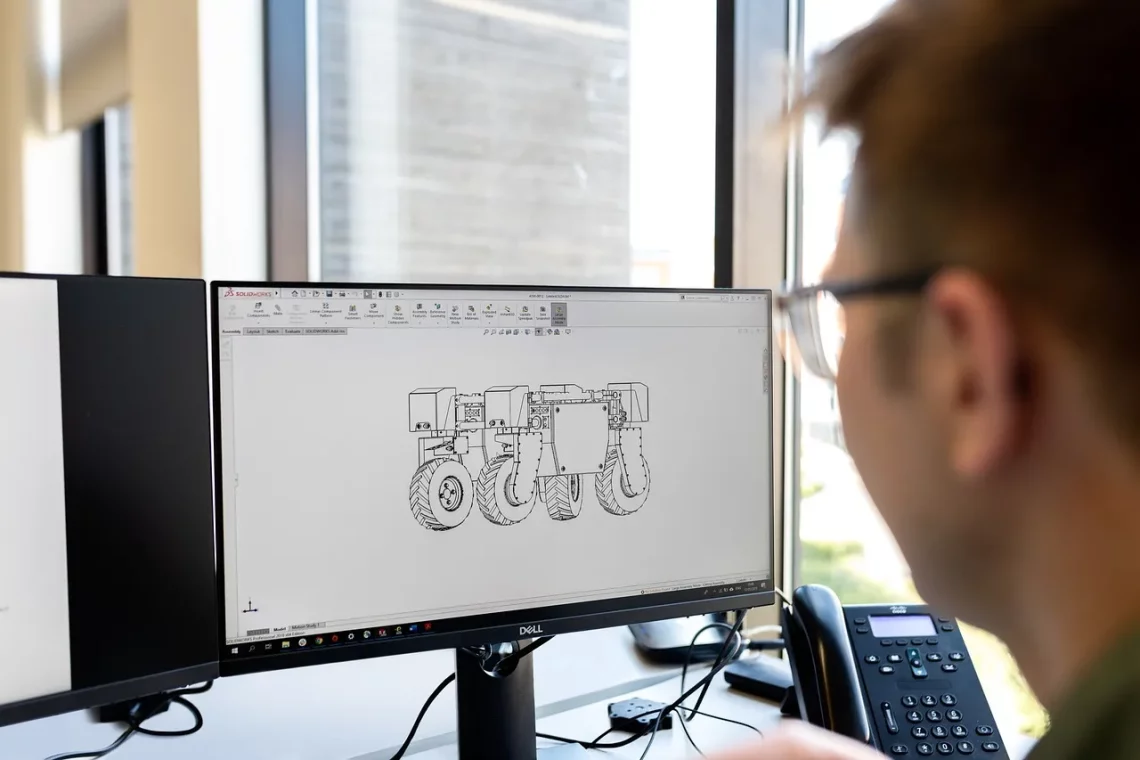

Moreover, the advent of digital tools and simulation software is revolutionizing the design process for tension bars. Engineers can now utilize advanced modeling techniques to predict how tension bars will behave under different loading scenarios. This allows for more optimized designs that maximize performance while minimizing material usage, thus contributing to sustainability goals.

The integration of building information modeling (BIM) into the design and construction processes is also enhancing the way tension bars are incorporated into structures. BIM enables engineers to visualize tension bar placements and their interactions with other structural elements in a digital environment. This holistic approach can lead to better coordination among disciplines, reducing errors and improving the overall efficiency of the construction process.

In addition to technological advancements, there is an increasing emphasis on sustainability and environmental considerations in structural engineering. As society becomes more conscious of its impact on the planet, the demand for environmentally friendly materials and construction practices will continue to grow. Tension bars made from recycled or renewable materials, or designs that minimize waste and energy consumption, could become more prevalent in future projects.

Finally, regulatory standards and codes are likely to evolve to reflect these advancements and address new challenges in structural engineering. Engineers must remain informed about these changes to ensure compliance and to utilize best practices in design and construction.

In summary, the future of tension bars in structural engineering is bright, driven by innovation and a commitment to safety and sustainability. As technology continues to advance, tension bars will play an increasingly vital role in creating resilient, efficient, and environmentally responsible structures, ensuring the safety and well-being of communities for generations to come.